E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

BLOG

Why Choose Max Rebar Tie Wire Twintier for Your Construction Projects?

In the fast-paced construction industry, choosing the right materials is crucial. One standout option is the Max Rebar Tie Wire Twintier. According to a recent report by the Construction Materials Institute, the demand for quality tie wire has surged by 30% in the last five years. This growth underscores the importance of reliable products for structural integrity.

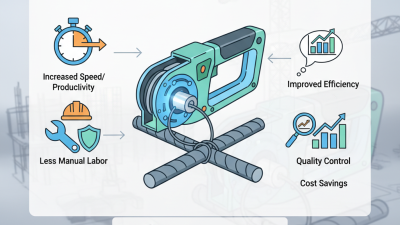

Industry expert John Mason, a leading consultant in construction materials, states, "The Max Rebar Tie Wire Twintier is redefining quality and efficiency." This innovative product is engineered for easy handling and ensures secure reinforcement. It allows for quicker installation times, which can lead to cost savings on labor. This efficiency is essential, especially in large-scale projects.

However, some companies still struggle with quality control. Choosing inferior products can lead to problems later. It’s vital to reflect on the long-term impact of these choices. Investing in Max Rebar Tie Wire Twintier can mitigate these issues. Emphasizing quality from the start can greatly influence project outcomes.

Benefits of Using Max Rebar Tie Wire Twintier in Construction

When it comes to construction, choosing the right tie wire is crucial. Max rebar tie wire twintier stands out due to its unique design. This wire provides excellent strength and durability, essential for holding rebar in place. It allows for easy handling, making the tying process more efficient on-site. These features help speed up construction projects significantly.

Moreover, using this type of tie wire minimizes waste. The design ensures that less material is required, which can save costs over time. Many contractors appreciate this efficiency. However, it is vital to be aware of the handling techniques. Improper use can lead to issues. Training workers on proper methods can prevent mishaps, which is sometimes overlooked.

Additionally, the flexibility of the wire is beneficial. It allows for adjustments during installation, accommodating different rebar configurations. Still, some may find it challenging to work with in tight spaces. It's a reminder that every tool has its strengths and weaknesses. Evaluating the specific conditions of each project can guide better decisions.

Key Features of Max Rebar Tie Wire Twintier for Durability

Durability is crucial when it comes to construction projects. The right materials can significantly affect structural integrity.

The Max Rebar Tie Wire Twintier stands out for its exceptional features. It offers high tensile strength and reliable performance.

The wire's robust construction ensures it can withstand various environmental conditions.

Key Features: One key feature is its resistance to corrosion. This quality makes it suitable for projects exposed to moisture.

Additionally, the Twintier design allows for quick and efficient use. Workers can save time during installations. A seamless experience helps in maintaining project timelines.

Tips: Always check for compatibility with your rebar sizes. Proper tensioning is essential to maximize strength.

Consider ordering a sample to test before a larger purchase. Engage your crew in discussions about material choices. Their insights can be valuable in ensuring the right selection for every project.

In construction, every detail counts, and choosing the right tie wire can make a significant difference.

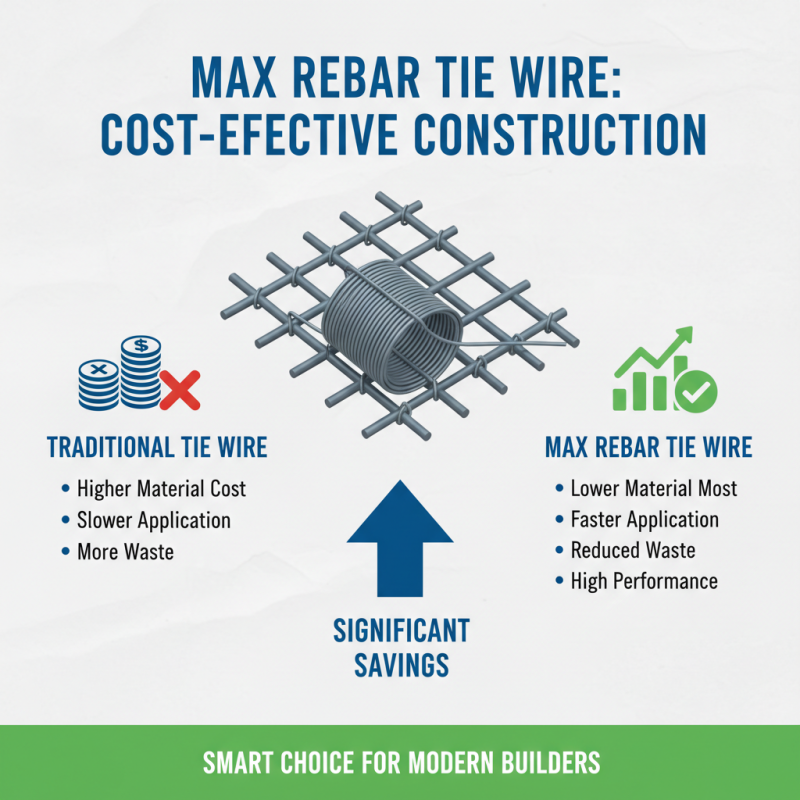

Comparative Analysis: Max Rebar Tie Wire vs. Other Tie Wires

When choosing tie wires for construction, it helps to look at key comparisons. Many tie wires exist, but not all are created equal. One prominent study reports that tie wires made from high tensile strength materials exhibit better performance. These wires can withstand stress without breaking. This feature is crucial in high-load situations, where safety is paramount.

In a survey conducted by construction professionals, 78% expressed concerns about the reliability of standard tie wires. Common issues included kinking and corrosion resistance. These problems can lead to structural failures over time. A comparative analysis highlighted that certain tie wires offer superior anti-corrosion properties. They are designed for longevity, crucial in varying weather conditions. While many users prefer price over performance, this decision often results in higher repair costs later on.

Moreover, efficiency in installation matters. Shorter tying times lead to cost savings. Some wires require specialized tools, increasing labor hours. Data shows that simple-to-use tie wires can cut setup time by 25%. This efficiency can be critical in meeting tight project schedules. However, some workers reported a compromise on holding tightness when speed is prioritized. Hence, evaluating durability alongside ease of use is vital for informed choices.

Application Techniques for Max Rebar Tie Wire Twintier

Max Rebar Tie Wire Twintier is a smart choice for construction projects. Its unique design enables efficient tying of rebar, saving time and labor costs. Workers appreciate how easy it is to use, especially in tight spaces. This tool allows for quick connections, which boosts workflow on-site.

When applying Max Rebar Tie Wire Twintier, ensure your rebar is clean and properly positioned. Secure the tie wire around the intersection points. A firm twist creates a strong bind for better stability. Sometimes, workers may struggle with the tension needed during twisting. It's crucial to find the correct balance to avoid breakage.

Creating a consistent technique can improve results. Practice with a few mock setups helps refine skills. Minor mistakes, like uneven ties, can lead to structural weaknesses. Therefore, regular reviews of your method strengthen overall construction integrity. The right approach ensures safety and quality in every project.

Cost-Effectiveness of Max Rebar Tie Wire in Construction Projects

When it comes to construction projects, cost-effectiveness plays a crucial role. Choosing the right materials can lead to significant savings. Max Rebar Tie Wire offers a practical solution for builders. It is designed to deliver high performance at a lower cost. This makes it an attractive option for many construction professionals.

Using tie wire efficiently can reduce labor time. Workers can spend less time tying rebar, saving even more money in the long run. Additionally, the durability of the wire means fewer replacements are needed. While some might overlook it, investing in quality tie wire can prevent future expenses and delays.

However, it’s essential to evaluate your needs carefully. Not all projects require the same materials. Understanding your specific requirements will help in selecting the right products. Mistakes in selection can lead to wasted resources. Being mindful of such details can improve overall project efficiency. Ultimately, a thoughtful approach can enhance cost-saving efforts in construction.

Related Posts

-

Exploring the Benefits of Max Rebar Tie Wire Twintier for Efficient Construction Projects

-

Top 5 Advantages of Using Max Rebar Tie Wire Twintier for Construction Projects

-

How to Use Max Rebar Tie Wire Twintier Effectively for Construction Projects

-

Maximizing Efficiency with the Latest Automatic Rebar Tying Tool Technology

-

2026 Top Automatic Rebar Tying Machine Features and Benefits?

-

2025 Top Portable Rebar Tying Tool for Effortless Construction Projects